Experimental verification of 3 smelting and pouring schemes for ductile iron

Furan resin sand is generally used as the molding material for large-scale ductile iron castings produced in my country. It is produced in a single piece, with a large pouring weight and a complex structure. The quality and performance requirements of the castings are very high. Some casting defects, especially shrinkage defects, often appear in the smelting process. It will cause the casting to be scrapped and cause major economic losses, especially the QT400-18AR material, which has high strength, high elongation, and impact value requirements. While ensuring the mechanical properties of such thick and large parts, it is not easy to avoid graphite floating and shrinkage defects.

Through the design of sample experiments, the analysis equipment of Nanjing Difeng Company was used to study the influence of chemical composition and pouring temperature on the defects of graphite floating and shrinkage caused by the solid sample with a wall thickness of 180mm. It is then applied to the production of ductile iron thick-walled parts to obtain good quality castings.

Equipment and material preparation

Self-use high-purity pig iron, pure low-manganese scrap, high-magnesium spheroidizing agent, 75#FeSi inoculant; Nanjing Difeng low-magnesium spheroidizing agent, inoculant; 1.5 ton intermediate frequency smelting furnace 500kg spheroidizing bag, 500kg tundish. Nanjing Difeng EPIC thermal analyzer, carbon and sulfur analyzer, spectrometer.

Design a solid sample wooden model

The size is 600mm×400mm×180mm, and the process will be trial-produced. The wall thickness of 180mm is used to cover the thick and large pieces of ductile iron products produced by the company. It is quite representative. The riser and runner system are set up and the bottom casting is used. The casting weight is 500kg.

Melting and pouring scheme design

Use 1.5t smelting intermediate frequency furnace to melt 1.5t molten iron, inoculate 500kg each time for spheroidization, and pour 1 box of small sample test pieces. A total of 3 cases of test pieces were poured in 1 furnace. Different smelting and pouring schemes are designed as follows:

The first option

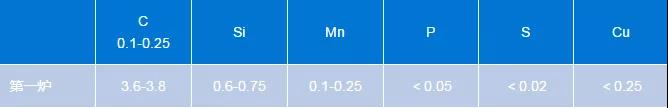

Charge ratio: 85% pig iron, 15% low manganese scrap steel; chemical composition control:

Adopt spheroidization inoculation treatment plan:

First, 500kg of iron is tapped into the tundish, 1.3-1.5% high-magnesium nodulizer, 0.3-0.4% inoculant and 0.8% covering agent are pre-embedded in the spheroidizing bag, and the bag is turned over for spheroidizing treatment. After the spheroidizing treatment is completed, the inner surface of the bag is put in After the flow inoculant is completely smashed, take samples and use the EPIC instrument for analysis and testing.

1.2% Nanjing Difeng Nodulizer, 0.8-1.0% Covering Agent, 0.4% Glass Broken is embedded in the spheroidizing bag, and iron is directly tapped into the spheroidizing bag, and 0.5% Nanjing Difeng Inoculant is put in at the same time. After the spheroidization is completed, the Nanjing Difeng follow-up inoculant sprinkled on the surface is sampled and analyzed using an EPIC instrument.

1.2% Nanjing Difeng spheroidizing agent, 0.8-1.0% covering agent, and 0.4% glass cullet are pre-embedded in the spheroidizing bag, and iron is tapped directly into the spheroidizing bag, and 0.5% Nanjing Difeng inoculant is put in at the same time. After the spheroidization is completed, the Nanjing Dysprosium peak flow inoculant sprinkled on the surface is sampled and analyzed using an EPIC instrument.

The second option

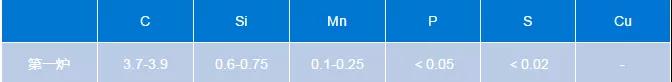

Charge ratio: 65% pig iron, 35% low manganese scrap steel; chemical composition control:

Adopt spheroidization inoculation treatment plan:

Directly tap 500kg of iron to the tundish, and pre-embed 1.2% Nanjing Difeng nodulizer, 0.8-1.0% covering agent and 0.4% glass cullet in the spheroidizing bag, and directly tap the iron into the spheroidizing bag, and put in 0.5% Nanjing Dysprosium at the same time Peak inoculant, after the spheroidization process is completed, put the Nanjing Difeng Follow-on Inoculant on the inner surface of the bag, smash it out completely, and use the EPIC instrument for sampling for analysis and testing.

Directly tap 500kg of iron to the tundish, and pre-embed 0.95% Nanjing Difeng Low Magnesium Nodulizer, 0.65% Nanjing Difeng Covering Agent, 0.2% Scrap Steel Sheet and 0.1% Slag Remover in the spheroidizing bag, and then tap the iron directly to the tundish. Spherical package. After the spheroidization is completed, the surface is sprinkled with the Nanjing Difeng Flow Inoculant, completely smashed, and the sample is analyzed and tested with an EPIC instrument.

Directly tap 500kg of iron to the tundish, and embedded 1.2% Nanjing Difeng nodulizer, 0.3% covering agent, 0.2% Nanjing Difeng inoculant, 0.5% steel scrap and 0.1% slag remover in the spheroidizing bag. Cast iron directly to the spheroidizing bag, and put in 0.35% Nanjing Difeng Inoculant at the same time. After the spheroidization is completed, the surface is sprinkled with the Nanjing Difeng Flow Inoculant, completely smashed, and the sample is analyzed and tested with an EPIC instrument.

The third option

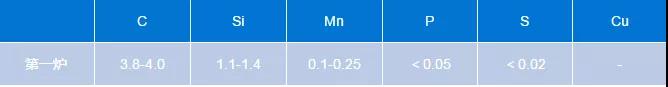

Charge ratio: pig iron 65%, scrap steel 35%; chemical composition control:

Adopt spheroidization inoculation treatment plan:

Directly tap 500kg of iron to the tundish, and pre-embed 1.2% Nanjing Difeng low-magnesium nodulizer, 0.8% covering agent and 0.1% slag remover in the spheroidizing bag, and directly tap the iron to the spheroidizing bag, and put 0.55% of Nanjing Difeng Inoculant, after the spheroidization is completed, the inner surface of the bag is put into Nanjing Difeng Flow Inoculant, completely smashed, and the sample is analyzed and tested with an EPIC instrument.

Directly tap 500kg of iron into the tundish, and pre-embed 1.2% Nanjing Difeng Low Magnesium Nodulizer, 0.8% Nanjing Difeng Covering Agent, and 0.1% Deslagging Agent in the spheroidizing bag, and directly tap the iron into the spheroidizing bag and put in at the same time 0.55% Nanjing Difeng Inoculant. After the spheroidization is completed, the Nanjing Difeng follow-up inoculant sprinkled on the surface is completely smashed, and the sample is analyzed and tested with an EPIC instrument.

Directly tap 500kg of iron to the tundish, and the spheroidizing bag is embedded with 1.2% Nanjing Difeng low-magnesium nodulizer, 0.3% covering agent, 0.2% Nanjing Difeng inoculant and 0.1% slag remover, and direct iron to In the spheroidization package, 0.35% of Nanjing Difeng Inoculant was injected at the same time. After the spheroidization is completed, the Nanjing Difeng follow-up inoculant sprinkled on the surface is completely smashed, and the sample is analyzed and tested with an EPIC instrument.

Sample test conclusion

Use the appropriate carbon equivalent value

By adjusting the ratio of the molten iron in the first furnace and the second furnace, the LET value of the original molten iron of the second furnace is higher than that of the first furnace, and the G1 value is smaller than that of the first furnace. Through adjusting the charge ratio of the second and third furnaces, replacing pure low-manganese scrap with lump steel, the LET value is close, and the G1 value is significantly reduced after the recarburization. Therefore, increasing the carbon content can improve the nucleation ability of the original molten iron and reduce The shrinkage tendency has little change with the type of scrap.

Use proper spheroidization inoculation process

Through the comparison of the first furnace A plan with the B plan and the C plan, the factory's own spheroidizing agent and inoculant, using the existing treatment methods, the shrinkage tendency and nucleation ability of the molten iron are both poor; the second furnace plan A. Plan B and Plan C show that when the spheroidizing agent dosage is 1.2% and the inoculant dosage is 0.5, the treatment effect is the best, and the difference between pre-embedding and tapping is not big; through the third furnace plan A, B Comparing with, C, there is no obvious difference in the effects of the three treatment schemes, and the cause of the change is the CE value of the original molten iron. In short, using high CE value (C3.7-3.9, Si2.1-2.4), using Nanjing Dyfeng Nodularizer Inoculant, the dosage of Nodularizer 1.2%, Nanjing Dyfeng Inoculant 0.5% and Flow Inoculant can be obtained Hot metal with high nucleation ability and low shrinkage tendency makes it easier to obtain ductile iron castings that meet the quality requirements.

Application conclusions for production

Use sample test conclusions to produce ductile iron thick-walled parts, the plan is as follows:

The melting weight is 20t, the charge ratio is 65% pig iron, 35% steel scrap, Nanjing Difeng nodulizer 1.2%, Nanjing Difeng inoculant 0.5% + flow inoculant, raw molten iron C3.7-3.9, Si2.2-2.5 , Mn≤0.3, P≤0.05, S<0.02, carry out production, take the casting test bar attached to the casting for testing, and dissect and observe the casting body.

After the dissection, the processing surface was inspected, and there was no graphite floating and shrinkage defects after processing, and the program was successful.

Summarize

1. Thick-walled ductile iron parts are difficult to control in the production of ductile iron. They have the characteristics of large wall thickness, slow cooling, containing Mg and other elements, and high shrinkage tendency. Defects and scrap during production are prone to cause economic losses. . Especially for castings of QT400-18AR grade, its performance requirements: tensile performance Rm≥390; yield strength Re≥240; elongation A≥18; average impact value KV2≥14, minimum impact value KV2≥11, which requires higher requirements.

2. Through the small sample process test, the pouring small sample test piece is tested for different chemical components and different spheroidization inoculation treatment methods. The EPIC equipment of Nanjing Difeng Company detects the shrinkage tendency of the molten iron, and determines the appropriate chemical composition and the proper nodularization inoculation treatment method to obtain the molten iron with the smallest shrinkage tendency.

3. Apply the data obtained from the small sample process test to actual production to form a clear and stable production plan for the production of ductile iron thick-walled parts. Through inspection of the attached casting test bar and anatomical surface observation, it is determined that the plan is effective and the casting is produced. The quality is good and meets the quality requirements.