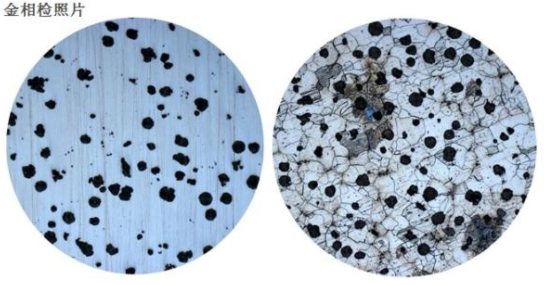

Want to improve the performance of ductile iron? Choosing the spheroidization method is the key!

Nodular cast iron is obtained by spheroidization and inoculation treatment to obtain nodular graphite, which reduces the fracture effect of graphite on the matrix, effectively improves the mechanical properties of cast iron, and obtains higher plasticity, toughness and strength. Nodular cast iron is a high-strength cast iron material developed in the 1950s. Its comprehensive properties are close to steel. It is based on its excellent performance that it has been successfully applied to some complex forces, with relatively high requirements for strength, toughness and wear resistance. High parts. Nodular cast iron has rapidly developed into a cast iron material second only to gray cast iron and widely used. People have higher and higher requirements for the performance of ductile iron. A variety of spheroidizing treatment methods can be used in the production of nodular cast iron. These spheroidizing treatment methods have their own advantages and disadvantages, and enterprise engineers need to choose and apply reasonably according to actual production conditions.

Pressure plus magnesium

Since magnesium has a low boiling point (1107°C) and is difficult to dissolve in molten iron, and the temperature of molten iron can reach 1500°C during spheroidization, magnesium easily reacts violently in molten iron, leading to its lower absorption Rate. When the pressure of the medium surrounding magnesium increases, the boiling temperature of magnesium increases correspondingly, the burning loss of magnesium decreases, and the absorption rate of magnesium increases. Based on this principle, the pressure adding magnesium method was developed. According to the different pressure building methods, it can be divided into external pressure type and self-built pressure type two pressure adding magnesium methods. The external pressure type used in the early days was to place a processing bag full of molten iron in a closed pressure tank, and build the required pressure by compressed air or nitrogen. The other is to use magnesium vapor to build the pressure in the molten iron ladle. The latter is to add pure magnesium to the sealed molten iron ladle. Magnesium quickly generates a large amount of magnesium vapor in the molten iron ladle. Part of this vapor is passed through the molten iron. The molten iron is absorbed, and the other part escapes and quickly establishes a saturated vapor pressure corresponding to the temperature of the molten iron in the space inside the ladle. At this time, magnesium no longer boils and vaporizes and is lost. The advantages of the pressure-added magnesium method are that pure magnesium is used for spheroidization, and the absorption rate of magnesium is high, up to 70% to 80%, and there is no smoke and dust during the treatment process, and the labor environment is good. The disadvantage is that the processing equipment requirements and costs are relatively high; the operation is complicated and strict; the processing time is long and the molten iron cools more; the pressure during the spheroidizing process is high, and industrial accidents are prone to occur.

pour-over process

The spheroidization method is currently the most widely used spheroidization method at home and abroad. The treatment package used is usually a dam type spheroidizing treatment package. In order to reduce the intensity of the reaction between molten iron and magnesium and the volatilization rate of magnesium vapor, the impulse method usually uses an alloy spheroidizing agent with a lower magnesium content. During the spheroidizing process, first put the spheroidizing agent into one side of the dam, cover the top with ferrosilicon alloy, tighten it slightly, and then cover the rust-free iron filings, steel plate or other covering agent. When spheroidizing, the molten iron should be flushed into the other side of the molten iron ladle as much as possible. The absorption rate of magnesium in the flushing method is generally 30% to 50%. In order to improve the spheroidizing effect, the ratio of the height to the diameter of the treatment package can be increased; low-magnesium alloy spheroidizing agent is used; reasonable molten iron temperature and covering dosage. The advantages of the flushing method are simple processing methods and equipment, easy operation, greater flexibility in production, and low technical content required, but the disadvantage is that the spheroidization process is more polluted by magnesium light and smoke. ; The absorption rate of magnesium is low.

Subcontracting

The subcontracting method is a spheroidizing method developed and patented by George Fischer. This method uses pure magnesium as a spheroidizing agent, which is suitable for treating molten iron with high sulfur content, and can better separate impurities such as magnesium sulfide and magnesium silicate from the molten iron, and the reaction between magnesium and molten iron is not very violent. The molten iron has less cooling and is safe to use, and the absorption rate of magnesium can reach 60% to 80%. The specific process flow is that before the spheroidization treatment, the subcontractor is placed horizontally, a quantitative molten iron is injected, and then the spheroidizing agent is added to the reaction chamber, the closing device is locked, and the cover is covered. Then turn the molten iron ladle to stand upright. At this time, the molten iron enters the reaction chamber through the small holes on the reaction chamber. The flow rate is related to the area ofthe small holes and the static pressure in the molten iron ladle. Magnesium vaporizes by heating, forming a magnesium vapor pressure in the reaction chamber. When the pressure exceeds the static pressure of the molten iron in the ladle, the molten iron stops entering, and the latent heat of vaporization of magnesium reduces the temperature in the reaction chamber; the vapor pressure also drops, and the molten iron enters the reaction again. This kind of automatic adjustment can make the magnesium react with the molten iron relatively smoothly. The spheroidizing process of the subcontracting method also produces large magnesium light and smoke, and the small holes of the reaction chamber in the subcontracting are easily blocked by molten iron or molten slag. It is troublesome to clean and maintain the size of the small holes. The spheroidizing method is difficult Continuous processing of molten iron.

Core-spun wire feeding method

The cored wire feeding method was first used in the steelmaking industry, and then the technology was promoted to the foundry industry. At present, industrial developed countries generally apply wire feeding technology in the production of ductile iron castings. However, the application of this technology to ductile iron production in China started late. It has not been widely used in the production of ductile iron castings and is in the promotion stage. The application of wire feeding method to produce ductile iron parts is simply to insert the cored wire coated with magnesium and other alloy elements directly into the molten iron for spheroidizing treatment to produce ductile iron. The entire spheroidizing process can be completely automation. The diameters of commonly used cored wires are generally 9mm, 13mm, and the built-in powder alloy generally contains 25% to 30% of magnesium. When there are special needs, a certain amount of RE, Ca, Ba, etc. are also added to improve the performance of the casting. The wire feeding machine can set parameters such as wire feeding speed, wire length, wire feeding mode, etc. During the processing process, the wire feeding machine continuously inserts the cored wire into the covered processing package according to the set parameter configuration through the transmission mechanism. In the molten iron, due to the pressure generated by the height of the molten iron, the effective flow of the cover to isolate the air, and the cored wire is continuously inserted into the molten iron at a certain speed, this can avoid the instantaneous large-scale explosion of magnesium vapor and ensure the safe addition of magnesium alloys , It can avoid a large amount of magnesium escape and burn, and improve the absorption rate of magnesium in molten iron. Generally speaking, the performance and quality of the alloy cored wire, as well as the wire feeding speed and the wire feeding amount are the key factors to ensure the success of the feeding wire spheroidization process. The shape of the treatment bag, the temperature of the molten iron, the sulfur content of the raw liquid water, and the sealing of the cover are also important factors that affect the effect of the spheroidization treatment. The advantages of cored wire feeding method spheroidization treatment are: good desulfurization and deoxidation effect, less temperature reduction, relaxation of the requirements for the original molten iron; high and stable magnesium absorption rate, small fluctuation range of residual magnesium content; spheroidization treatment There is less soot and magnesium during the process; precise and automatic control of alloy addition can be realized.

Covering method

The capping method was invented by the British Cast Iron Research Association and is widely used in the production of nodular cast iron abroad. During the spheroidizing process of the cover method, the alloy is added in the same way as the flushing method, and then the cover is placed on the processing bag and the periphery is sealed, and the molten iron is injected into the cover, and the molten iron will pass through the iron on the side of the cover. The liquid injection hole (the molten iron must not be directly aligned with the alloy stack) flows into the bag. In this way, the outside air can be completely isolated from the inside of the bag, reducing the oxidation and burning of magnesium, increasing the absorption rate of magnesium (usually 60% to 65% or more), and improving the working environment. After the spheroidization reaction is over, the cover is removed. The spheroidization effect of the cap-clad method is closely related to whether the diameter of the molten iron injection hole of the cap-clad is selected correctly. The correct diameter of the molten iron injection hole can ensure that a certain height of the molten iron is maintained in the lid; the time for all the molten iron to flow into the lid is the same as the spheroidization reaction time. The cover-pack method not only retains the advantages of simple equipment and easy operation of the flushing method, but also overcomes the shortcomings of the flushing method, such as serious magnesium oxidation burn loss, low absorption rate, large consumption of nodularizer, and poor labor environment. For many years, foundry workers have been using the advantages of the cover method to produce ductile iron, and are also constantly trying to overcome the shortcomings of the spheroidizing treatment method in use: the cover is difficult to lift and the operation is more difficult; When the cupola is used for continuous tapping, the weight of molten iron is difficult to accurately quantify. After continuous improvement, the spheroidizing process has been widely promoted and applied.

In-Type Method

The spheroidizing agent is placed in a specially designed reaction chamber in the pouring system. During the pouring process, the molten iron will react with the spheroidizing agent when it flows through the reaction chamber to perform spheroidizing treatment. In order to ensure the stability of the spheroidization process and reduce the burning loss, the dimensions of the reaction chamber and the pouring system must be strictly calculated. Generally, the reaction chamber is set in the runner under the sprue.

The magnesium absorption rate of the internal method is high, up to 70% to 80%, no magnesium light, no smoke, no spheroidization, and suitable for assembly line production of mechanized modeling. The disadvantage is that there are strict requirements on the temperature of the molten iron, the sulfur content, the composition of the spheroidizing agent, the size of the spheroidizing agent, the size of the reaction chamber, and the design of the pouring system. The subtle changes in these factors may cause the spheroidizing effect. Variety. In addition, this method is also prone to slag inclusions.

In general, the above six spheroidizing treatment methods have their own advantages and disadvantages. It is hoped that all ductile iron casting manufacturers can comprehensively evaluate each spheroidizing treatment method according to their own production conditions and conditions, maximize their strengths and avoid weaknesses, and choose their own ball. Chemical treatment method to ensure the quality of ductile